Successful adoption rate of IoT technology in various industries continues its rapid rise throughout past years. The Internet of Things in logistics and transportation plays a crucial role, as implementing IoT features significantly benefits both sectors in different ways.

According to IoT in Logistics Market Research Report, the global Internet of Things and logistics market reached a value of about $34.5 million in 2019. As the research states, almost a three-time rise in a market value is highly expected by 2030, predictably reaching about $100 million.

Example of an IoT application for transportation and logistics (image by Adam Balazy)

Let’s now find out what are the key benefits of adopting IoT in the logistics and transportation industry, along with the main use cases and challenges that companies may encounter in the supply chain process.

🧱 5 Layers of IoT in the Transportation Industry

IoT in transportation and freight transport presents 5 operational layers to set up a trustworthy system of goods shipment. These are:

- an application layer;

- a service layer;

- a sensing layer;

- a communication layer;

- and an infrastructure one.

Every piece of data requires proper communication to be delivered right into the service layer after being sensed and stored in an infrastructure layer. For a better understanding of the Internet of Things architecture in the transportation cycle, let’s have a brief acquaintance with these layers and their responsibilities:

Layer | Task | Components/Means | ||

|---|---|---|---|---|

Application Layer | Granting clients abilities to monitor the transportation of goods, vehicles, and road conditions, etc. via an application | Mobile applications, web & mobile dashboards, web applications | ||

Sensing Layer | Gather data from the sensors integrated into smart vehicles and other tracking devices | Cameras, RFID tags, Beacons, various tracking and monitoring systems and gadgets | ||

Communication Layer | Providing informational bridges between service and sensor layers. Transferring collected data | Wi-Fi, Cellular data, Wired Networks | ||

Service Layer | Structuring the gathered data and processing it per user’s requests through the application layer | Logistics Service Platform, Fleet Vehicle Service Platform | ||

Infrastructure Layer | Improving the quality and reliability of performance by using specific technologies | Cloud Storages, Big Data, Mapping Services | ||

📈 Benefits of using IoT in Logistics & Transportation

In modern world IoT abbreviation may also be considered as “innovation” and “improvement” for almost every possible case. Wherever the Internet of Things gets involved, it becomes significantly beneficial for the system, whether it’s healthcare IoT, fitness, or just an ordinary housekeeping one. As we are talking about the IoT in transportation and logistics industry, let’s see what are the benefits of implementing IoT technology.

- Improved Analytics. The higher level of IoT adoption, often starting with Internet of Things prototype development, leads to gathering more useful data by companies. With the right way of gathering and presenting the information, it becomes easier to build an efficient strategy that leads to greater success. Various sensors allow to analyze the inventory assets and transporting qualities to find the best way to optimize any logistics process. More data leads to better decisions.

- Saving. By the means of IoT in transportation and logistics, companies are given a chance to predict and avoid potential financial damage when it comes to unexpected failures. Factoring in the IoT software development cost allows for predictive capabilities, leading to quicker reactions to malfunctions and quality maintenance, thereby achieving higher profit and reducing waste on fixing.

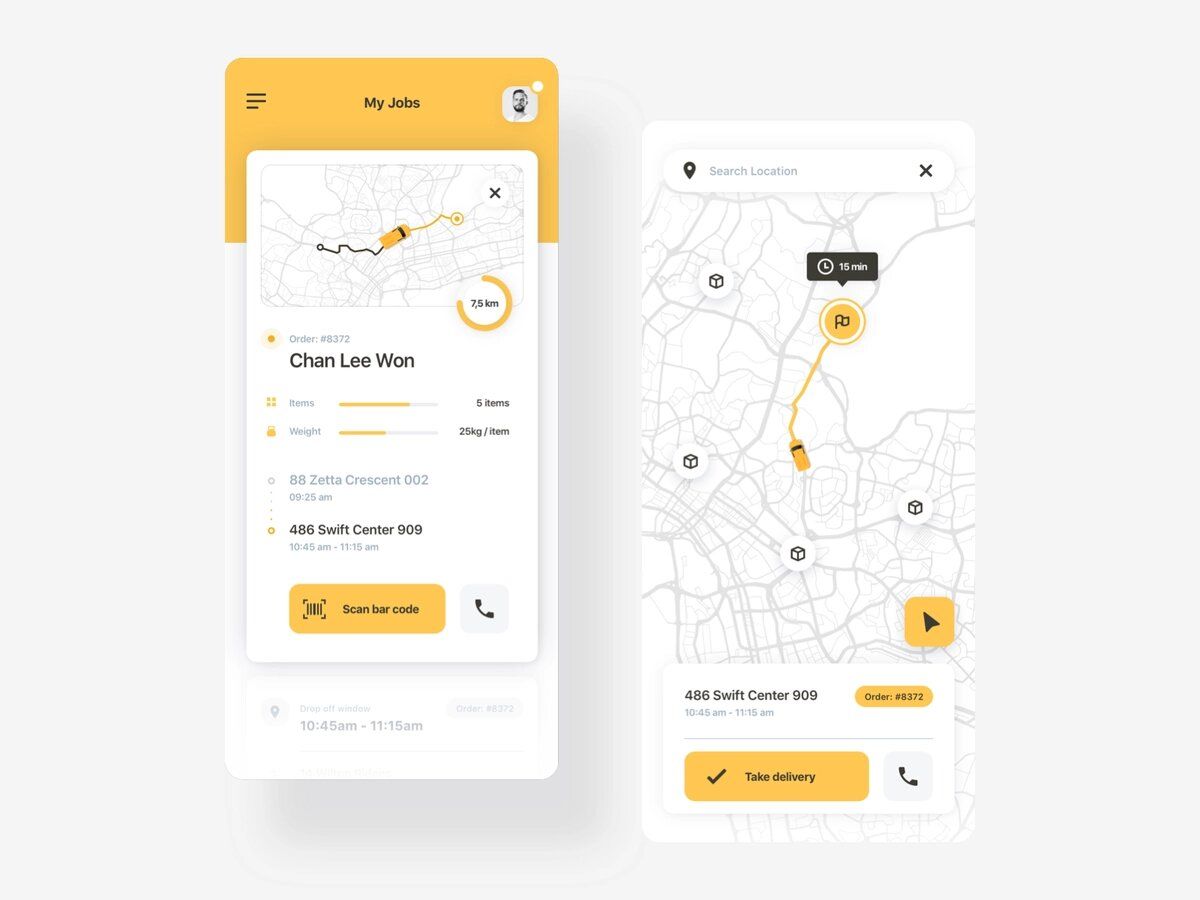

Logistics IoT applications are great in terms of predictive analytics, route optimization and transportation monitoring (image by Shakuro Graphics)

- Environment. Various sensors that transmit data in real-time grant flexibility in avoiding congestion and quick adaptation to sudden traffic pattern changes. Exactly the reduction of congestion and lesser energy waste because of quick reaction to new traffic patterns shows a great impact on the environment.

- Safety. IoT in logistics provides better security for employees in terms of fast issue detection. In case of an unexpected equipment issue, IoT sensors will notice it and react much faster, which can grant additional employee safety. For example, it doesn’t only provide real-time quality monitoring, it also may be programmed to automatically call an ambulance whenever sensors detect an emergency.

Additionally, wearables in IoT play a crucial role in enhancing employee safety by monitoring health metrics and sending real-time alerts in case of emergencies.

🚛 Internet of Things Use Cases in the Logistics Industry

Now that we are familiar with the advantages of the use of IoT in logistics, transportation, and areas such as smart agriculture IoT, let’s see how it can be implemented across these diverse fields.

Inventory Tracking

Thanks to IoT systems, it’s easier to monitor the safety of goods as well as quickly locate required products across gigantic warehouses. Inventory tracking also minimizes human-storage interactions which affects the number of possible inaccuracies.

Inventory tracking dashboards are used by logistics managers for predictive analytics and analyses (image by Istiak Ahmed)

Amazon Prime’s case is a good example here. Surprisingly, in Amazon’s warehouse items are not stored by similarity, vice versa the placing order is absolutely random. The reason behind this is a route management system that lets workers avoid wasting time sorting similar goods. Before placing an item on a shelf, employees scan it and automatically transfer the information about its location to the database. Whenever any product is ordered, a computer automatically creates the fastest route to its location for an employee, making the system even more time-saving.

Warehouse Management

Implementing the Internet of Things in warehouse management systems significantly impacts overall convenience and helps avoid a lot of potential issues.

With those sensors, managed efficiently with technologies such as React Native BLE manager, it’s possible to grant real-time tracking for goods that require special conditions in terms of storage. For example, remotely managing temperature levels hugely decreases the risks of an item being stored improperly, as the sensors allow employees to quickly react to any thermal issue and fix it without damaging the goods.

Besides the sensor integration to achieve peak efficiency, companies automatize warehousing with the help of robots and drones. Thus, Cainiao (China Smart Logistic Network) firm majority-owned by Alibaba opened a warehouse automated by over 700 robots to be completely prepared for a Singles’ Day shopping festival in 2018.

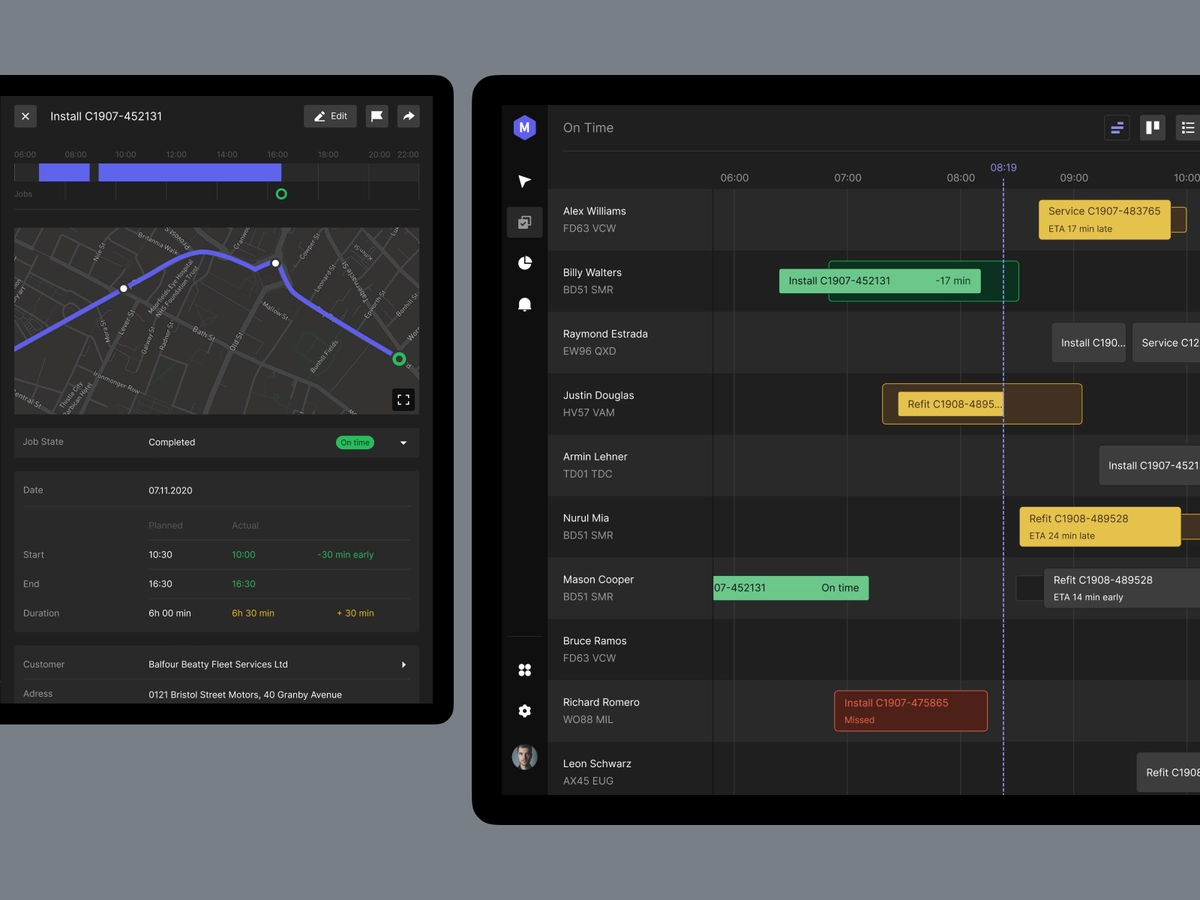

Smart Fleet Management

IoT and transportation solutions have revolutionized fleet management. The use of IoT sensors, along with connected car app development, considerably increases both vehicle tracking and driver monitoring, showcasing how to develop companion apps for efficient fleet management, similar to their application in IoT use cases in manufacturing to monitor and optimize equipment performance. With the Internet of Things and transportation solutions, it becomes possible to collect more information not only about the vehicle’s condition but also about the driver’s behavior. The advantages of more intense fleet management are quick reactions to sudden failures, proactive accident prevention, and the ability to track and prevent possible vehicle damage.

Example of smart fleet management presented in a timelined dashboard (image by Eugene Paryhin)

For example, IoT-enabled sensors, combined with IoT monitoring solutions, let you track fuel consumption levels, tire pressure, and the conditions of other inner parts of the vehicle. It also becomes possible to gather information about driving habits of an employee. Tracking the number of stops it takes him to travel a certain distance, average delivery speed, combined with the fuel consumption rates presented, gives an opportunity to create an optimal driving strategy so that the deliveries become more efficient.

Interested in the cost of developing an app like Lime? Our detailed guide sheds light on everything you need to know.

Predictive Maintenance

Maintenance and operation costs are usually a huge issue for various logistics companies in the transportation sector. Imagine the average cost of unexpected maintenance for a company conducting massive vehicle fleets. Basically, it may cost millions for a logistics company to deal with the malfunction they weren’t expecting at all.

However, in this situation, IoT in transportation and logistics implementation grants an incredible solution. As we can’t avoid maintaining vehicles from time to time, what if we change the word near our maintenance from “unexpected” to “predictive”? It gets much cheaper for a logistics company to maintain a vehicle when the malfunction is at its early stage. Thanks to IoT sensors monitoring every vital condition, spotting the first signs of a possible failure lets logistics companies save a significant amount of money on dealing with it.

This is where fleet management software development services can add value by building systems that automate fault detection, scheduling of maintenance, and alert automation.

📌 Through expert IoT application development, logistics companies can integrate predictive maintenance features into their fleet management systems, reducing downtime and operational costs.

Cargo Integrity Monitoring

With the help of smart labels, it’s now possible to track the conditions of any transported item and monitor the integrity of packages and delivery boxes.

It is much easier now to ensure a cargo’s integrity during transportation thanks to smart labels (image by Muharrem Huner)

The most popular use for such smart labels comes when the goods require special conditions to be maintained for quality delivery. For example, constant monitoring of frozen edible goods helps to prevent company losses in case of unexpected malfunction during transportation services.

Also, by using the smart tags, logistics companies may even reduce financial damage from the goods being stolen, as labels’ GPS tracking capacities may become quite handy.

As an example, there is a case study that covers the implementation of IoT-CMS in AOC Limited that covers the cold chain logistics with Chevalier Cold Storage and Logistics Limited in Hong Kong. In a four-stage system implementation and a 10-day data gathering, AOC Limited became able to monitor cargo conditions along with providing quality storing in real-time.

Drone Based Delivery

Among all the IoT solutions for supply chains, adopting drones for the transportation process has the greatest potential. As timely delivery is a top priority, minimizing human and route factors with IoT technologies will definitely be beneficial. Drone-based delivery not only makes route optimization strategies easier but also significantly reduces operating costs for the service provider, showcasing the Internet of Things in logistics for improved efficiency. Transportation IoT technologies such as drones are not yet ready for a complete adoption, however, some loud announcements have already been made.

So Amazon is already making progress in the eventual release of drone-based deliveries, and in the nearest future, we will see the beginning of the revolution in the transportation and logistics sector.

🔧 IoT Challenges in Logistics Processes

According to the Internet of things and its challenges in supply chain management research, adopting IoT comes with some challenges. Let’s take a look at the ones related to the supply chain process along with the issues that you shouldn’t ignore.

Integration

When we consider various potential challenges the first category to think of is definitely the integration part. What are the issues specifically related to integrating IoT features that shouldn’t be missed? Let’s find out the main ones.

- Scalability. As the smart devices in the supply chain will mostly serve a specific purpose it will lead to them being customized and set up exactly for the clear-cut usage in particular cases. It should be clear that with most of the possible customizations, there is a high risk of IoT being unscalable in the supply chain as well as the chances for device reusage in some diverse use cases considerably lower.

- Business model modifications. As we are talking about integrating IoT features into an already existing and functioning business, it’s vital for the chosen model to be suitable for such adoption. It is crucial that every component of the existing supply chain (manufacturers, suppliers, and distributors) can fit into the new business model and not be in disfunction. Or there is a risk that a previous business model will be no longer applicable to cover up the consequences of such an experiment.

- Financial awareness. IoT adoption without a doubt is a significant upgrade for a company, however, everything has its own price. It may be very challenging financially for many logistics companies to implement IoT features they are hugely expecting in their supply chain business. So taking such an important step without the realization of potential operational costs required may be very damaging to a company’s prosperity.

Operational

This section of challenges consists of the issues related to operational processes. What points should be considered in order to set up the highest functioning level and what usually stops the successful adoption of IoT in logistics industries.

- Weak planning stages. As IoT is a relatively new technology for companies to adopt, seeking expert IoT app development services can provide the necessary support and expertise for its integration. Unfortunately, it’s not enough to just realize the importance of IoT for a logistics business. Then there should always come thorough research and a clear strategy on how to adopt IoT properly and adapt it in the most beneficial way for a company. Nowadays, the lack of knowledge in IoT and consequent weak planning stages prevent many companies from accessing the benefits of IoT.

- Security and privacy issues. Successful Internet of Things and transportation integration is impossible without setting up proper security levels. As cyber intrusions and data leaks may cause severe damage to a company both financially and reputationally, security should be considered the top priority.

- Storage management. This challenge is partially related to the energy consumption issue we mentioned before. Logistics low power IoT devices generate a lot of information that should be stored properly in order to be practically convenient for use and presentation. The means of storing the big amount of generated data also require power for proper function, which should also be considered before integrating smart devices.

Social

Challenges that come with IoT are not only about operational or integration issues. It’s important to be aware of the challenges that involve social interactions such as gaining trust or re-educating employees. Let’s take a deeper look at them.

- Establishing Trustworthiness. Whenever a company decides to adopt the IoT, it often becomes necessary either to hire additional employees or to train some of them to be competent enough. In any of these cases, it becomes vital to gain trust among the stakeholders as well as to reach a complete agreement for the Internet of Things adoption. If a bigger percentage of them don’t have any idea how things operate with IoT, it may take some time to get their understanding. Unaware parties should trust the process and be confident about the positive outcome of implementing an IoT technology they have no clue about.

- Constant Environmental Variability. Although environmental challenges are also presented separately on the list, this challenge is not about ecology. The point is that almost everything in our world is dynamic. Whether it’s changing technologies or user behavior — nothing is absolutely stable and thus can’t be easily predicted. That’s why Internet of Things implementation involves adopting constant updating and adaptation to keep up pace with the environmental dynamics.

Environmental

After describing technical and social challenges we should also consider environmental awareness and the issues that lay beyond it. When it comes to the environment there are several challenges.

- Energy Issues. Nowadays the number of created smart devices continues to rise rapidly. Thus, there are also increases in the amount of energy required to power them. Although the whole world is looking forward to fully ecological power consumption, renewable energy sources may not be enough to fulfill the new power demands. Implementing a big number of smart devices may require a step back to traditional energy sources, which hugely affects the ecology.

- E-Waste. The more Internet of Things devices are manufactured the more technological disposals there will be. Basically, whenever an IoT device substitutes another gadget in a system — the e-waste rate increases. The disposal of various machinery and peripherals should be thoroughly considered with the adoption of the Internet of Things.

🤖 Emerging IoT Trends in Transportation and Logistics

The Internet of Things in logistics and transportation is driving revolutionary changes in the sector, reshaping supply chains and operations worldwide. In this section, we take a closer look at the future technological trends in the sector.

Low-Latency Networks and 5G

5G technologies significantly improve connectivity and data transmission capabilities, which in turn will transform IoT integration in logistics, supporting the development of smart road infrastructure through IoT connectivity technologies. The ultra-low latency and higher speeds of 5G internet connections will enable real-time decision-making, which is essential for time-sensitive tasks such as tracking and managing shipments.

Drones and Self-Driving Automobiles

IoT-driven drones and autonomous self-driving cars are revolutionizing logistics by optimizing routes and speeding up delivery procedures. The integration of AI and IoT sensors is creating fully automated logistics centers that can manage delivery, packaging, and inventory without human intervention.

For example, Amazon uses Prime Air drones to speed up the delivery of goods weighing less than five pounds, reducing delivery time to thirty minutes.

Data Security using Blockchain

The combination of IoT and blockchain technology will provide an unprecedented level of security and transparency of data in logistics. To cope with complexities such as international trade laws and cross-border transportation, blockchain technology ensures that transaction records are tamper-proof and can be tracked in real-time.

By switching to blockchain, logistics companies will be able to facilitate regulatory compliance, improve data quality, and reduce fraud.

Combining Machine Learning and AI

Logistics companies can make better decisions using predictive analytics that combine IoT with artificial intelligence and machine learning. Customers experience increased satisfaction, and operators save costs as these solutions improve demand forecasting, route calculations, replenishment processes, and overall customer service efficiency.

For example, FedEx manages real-time rerouting systems using AI-powered IoT technology and predicts delivery delays.

❓ How to Choose the Right Network for Transportation and Logistics

Companies planning to implement artificial intelligence in their logistics business must choose the right network solutions that support operational efficiency and protect data and future growth potential. The connection between IoT-based logistics depends on the uninterrupted availability of a network that tracks delivery information, as well as monitors fleets and develops supply chain operations. Deciding which network to use becomes tricky because you have several options, including 5G, LPWAN, Wi-Fi, and satellite.

In this section, we'll try to help you make the right decision when it comes to technology. Let's get started!

Define Your Needs: Requirements & Constraints

The type of logistics system you are building determines your network requirements. If your app relies on real-time data, such as real-time vehicle tracking, predictive maintenance alerts, or automated warehouse management, you need a low-latency, high-bandwidth network. On the other hand, if your application processes data in batches (e.g., periodic inventory updates), a low-power network may be sufficient.

Evaluate Network Options

The combination of 5G and LTE wireless technologies provides optimal functionality for instant tracking while enabling high-speed data transfer and AI-based computing. 5G provides AI models with advanced computing, which reduces the time it takes to process data sources.

LPWAN (Low Power Wide Area Networks with LoRaWAN, NB-IoT, and Sigfox) is the best solution for IoT sensors in warehouses and fleet monitoring when power consumption becomes critical. LPWAN provides long-distance communication with low power consumption.

Wi-Fi and private networks effectively serve warehouses, as well as any other facilities that require AI-based inventory tracking in specific operational ranges.

In certain regions where the reliability of cellular networks is unstable, satellite communications are a necessary link for long-distance cargo delivery. Global supply chain fleet management with AI produces better results thanks to well-established connectivity.

Consider Security and Reliability

Logistics applications process information containing sensitive operational and customer information. Choose a network that provides full data encryption and secure APIs, and complies with industry standards such as GDPR and ISO 27001. Mission-critical logistics operations require fully redundant systems that also include automatic failover capabilities.

📌 To further enhance security and reliability, companies should implement an IoT OTA update strategy to remotely deploy security patches and software updates, minimizing vulnerabilities across connected devices.

Optimize for Cost and Scalability

Your logistics application needs a network solution that can accommodate the growth of your operations. LPWAN provides affordable expansion options for deploying large sensor systems, and 5G supports the efficient implementation of AI-powered automated processes. Pay-as-you-grow business management allows you to optimize costs in the best way possible.

Test Before Deployment

Before making a final decision, test pilots should be conducted in different environments (urban areas and rural areas near warehouses) to evaluate the functionality of the network. Artificial intelligence algorithms require reliable, high-quality data to succeed, so network stability is a fundamental requirement.

🤔 Why Choose Stormotion for Implementing IoT Solutions in Transportation and Logistics

At Stormotion, we focus on creating modern IoT solutions to improve your business. Our EV Charging App Development Company provides innovative software solutions that improve real-time tracking and operational efficiency through our experience with electric vehicle mobility and charging solutions, as well as smart device integration capabilities.

We have experience in developing IoT-based applications for electric vehicle charging, as well as fleet management and asset tracking systems. Milence and DeftPower demonstrate our ability to create data-driven solutions that can be scaled to deploy electric vehicle charging platforms in the transportation and logistics sectors.

Milence app

(image by Stormotion)

Our team has excelled in BLE along with IoT connectivity, positioning us as a reliable IoT connectivity partner that facilitates efficient communication between vehicles, logistics centers, and cloud systems. Our cooperation with Egret (an IoT-based e-scooter app) proves our competence in real-time data tracking together with telematics systems and intelligent fleet management.

The platforms developed by Stormotion are capable of processing significant amounts of IoT data in real time and maintaining a secure infrastructure. Our team uses React Native together with Kotlin and AWS, as well as other advanced technologies to develop logistics and transportation applications that provide a wide range of promising features.

💡 Takeaways

In conclusion, we can confidently state that adopting the Internet of Things for Logistics and Transportation businesses is significantly beneficial to improving safety, profit, and reliability. The number of possible use cases for IoT systems in shipping and logistics is game-changing and shouldn’t be underestimated. If you choose a prosperity course for your logistics or transportation project — implementing IoT is definitely the most beneficial and reliable step you can take.

If you have any questions or need help with integrating IoT features into your logistics or transportation project, let us know. We will be happy to help you meet your business needs with an outstanding product!

![Stormotion client Pietro Saccomani, Founder from [object Object]](/static/40e913b6c17071a400d1a1c693a17319/b0e74/pietro.png)